3D Printing

Get a Quote

Have Questions? Get in touch and we will reach out shortly

3D Printing

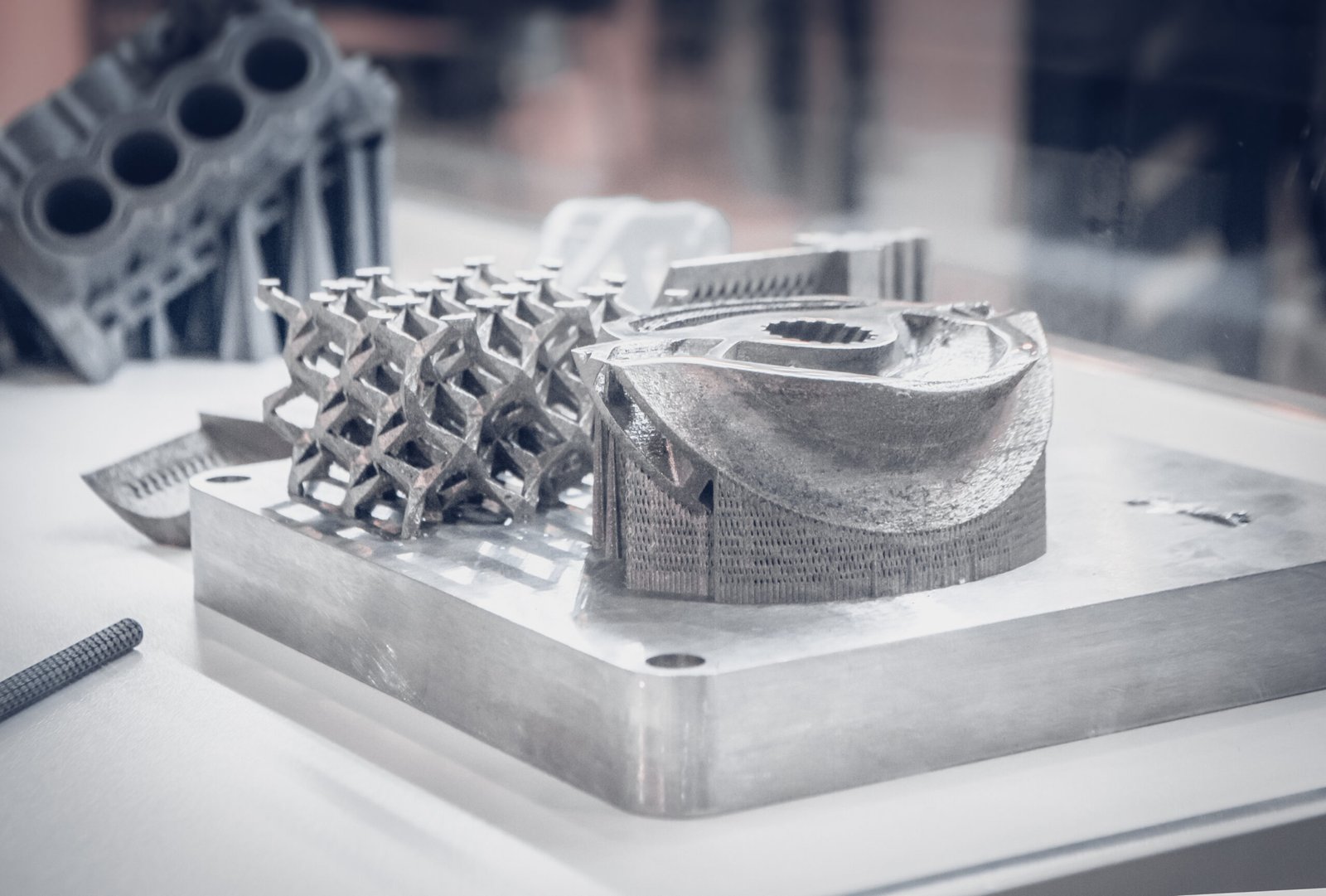

At Grefit Prototype, our 3D printing services provide innovative and versatile solutions for creating high-quality prototypes, custom parts, and production components. Utilizing advanced additive manufacturing technologies, we offer exceptional precision, flexibility, and efficiency to meet a wide range of industrial and commercial needs. Our 3D printing capabilities include both metal printing and SLA printing, allowing us to cater to diverse applications with specialized requirements.

3D Printing Overview

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by depositing material layer by layer based on digital models. This technology enables rapid prototyping, complex geometries, and customizations that are often challenging or impossible with traditional manufacturing methods. At Grefit Prototype, we leverage cutting-edge 3D printing technologies to deliver high-quality results tailored to your specific needs.

About Metal Print – DMLS

- Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM): These methods use a laser to selectively melt or sinter metal powder. DMLS operates at a lower temperature, fusing particles together, while SLM fully melts the powder, resulting in denser parts. These processes are ideal for producing high-performance, complex components, often used in industries like aerospace, automotive, and medical implants.

Advantages

Metal 3D printing produces parts with comparable strength and durability to traditionally manufactured metal components, making it suitable for functional and structural applications.

Metal printing allows for the creation of intricate designs and complex geometries that are difficult to achieve with conventional machining or casting methods.

We offer a variety of metal materials, including stainless steel, titanium, aluminum, and cobalt-chrome, each with unique properties suited to different applications.

Metal printing enables fast turnaround times for prototypes and small production runs, reducing development cycles and accelerating time-to-market.

Applications and Use Cases

Aerospace Components

Producing lightweight, high-strength parts for aerospace applications, including brackets, housings, and structural components.

Medical Devices:

Creating customized implants, surgical instruments, and prosthetics with precise specifications and biocompatibility.

Automotive Parts

Manufacturing high-performance parts such as engine components, brackets, and tooling with complex geometries.

Industrial Equipment

Fabricating custom tooling, fixtures, and replacement parts for machinery and equipment.

SLA Print

Advantages and Use Cases

SLA printing offers exceptional accuracy and fine detail, making it suitable for producing intricate models and prototypes with smooth surfaces.

We use a range of resins, including standard, high-temperature, and flexible resins, to meet diverse application needs and achieve specific material properties.

SLA-printed parts have a smooth surface finish, reducing the need for extensive post-processing and providing high-quality aesthetics.

SLA technology enables quick turnaround times for prototypes and design iterations, allowing for faster development cycles and validation.

Consumer Products

Producing detailed prototypes and product models for consumer goods, including electronics, wearables, and accessories.

Medical Model

Creating accurate anatomical models, surgical guides, and dental prosthetics with high precision.

Architectural Models

Fabricating detailed architectural and scale models for presentations and client reviews.

Toy Design

3D printing enables quick prototyping and customization of intricate toy designs.

Custom Solutions and Support

At Grefit Prototype, we offer customized 3D printing solutions to meet your specific project requirements. Our team of experts provides support throughout the design and production process, offering guidance on material selection, design optimization, and post-processing. Whether you need assistance with prototype development, production parts, or custom designs, we are here to help you achieve the best results.

Quality Assurance

Quality assurance is a key aspect of our 3D printing services. We implement rigorous quality control procedures to ensure that each part meets the highest standards of accuracy and performance. Our quality checks include dimensional verification, material testing, and visual inspections to confirm that the printed parts adhere to your specifications and requirements.

Sustainability

Grefit Prototype is committed to sustainability and environmentally responsible practices in our 3D printing operations. We strive to minimize waste and reduce our environmental impact by using recyclable materials and implementing efficient manufacturing processes. Our dedication to sustainability aligns with our goal of delivering high-quality products while protecting the environment.

Conclusion

3D printing services at Grefit Prototype offer innovative and versatile solutions for producing high-quality prototypes, custom parts, and production components. Our expertise in metal printing and SLA printing ensures that we can meet diverse application needs with precision and efficiency. Contact us today to discuss your 3D printing requirements and discover how our services can enhance your projects and applications.

The Process of 3D Printing Services

Our customers from various industry such as electronics, consumer products, agriculture, automotive, robotic, etc.

Design and Material Selection

Share your 3D model or design requirements with us. We will help you choose the best materials, whether metal or plastic, to ensure your project meets its functional and aesthetic needs.

3D Printing Process

Using cutting-edge 3D printing technology, we turn your design into reality. Whether you need metal printing for strength or SLA printing for precision, we ensure accuracy and high-quality results.

Post-Processing and Finishing

After printing, we refine your part through post-processing. This includes tasks like support removal, sanding, and polishing to enhance both functionality and appearance.

Final Inspection and Delivery

We perform a thorough quality check to ensure your part meets all specifications. Once it passes inspection, your finished product is delivered and ready for use.

3D Printing Services FAQs

3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects by layering materials based on digital models. At Grefit Prototype, we utilize advanced technologies, including metal printing and SLA (Stereolithography) printing, to produce high-quality prototypes and custom parts with exceptional precision and flexibility.

Our 3D printing services support a wide range of materials, including various plastics for SLA printing and metals for metal printing. The choice of material depends on the specific requirements of your project, such as strength, flexibility, heat resistance, and aesthetics.

3D printing offers numerous benefits, including rapid prototyping, design flexibility, and reduced material waste. It allows for the quick iteration of designs, enabling faster time-to-market while maintaining high quality and precision in the final product.

Our 3D printing services cater to a variety of industries, including aerospace, automotive, healthcare, consumer products, and manufacturing. We provide tailored solutions for diverse applications, from intricate prototypes to functional production parts.

At Grefit Prototype, we employ advanced additive manufacturing technologies and strict quality control processes to ensure that every 3D-printed component meets your exact specifications. Our experienced team monitors each stage of the printing process to deliver reliable and high-quality results tailored to your needs.

Why Choose Us

Unmatched Expertise and Innovative Solutions

At Grefit Prototype, we are dedicated to delivering excellence in every aspect of our work. Here’s why you should choose us for your prototyping and manufacturing needs

We leverage cutting-edge technology to solve complex manufacturing challenges.

Our skilled machinists and engineers ensure top-notch quality and craftsmanship.

Tailored CNC machining services to meet your unique project needs.

Achieve exact specifications with consistent accuracy for every part..

Capable of adapting to changing project needs and production scales.

Affordable machining services without compromising on quality

Extensive range of materials, including metals, plastics, and composites, for versatile applications.

Reliable and timely delivery to keep your projects on track

Reliable service with a history of successful projects and satisfied clients.