Speed

Fast turnaround times reduce the product development cycle.

Cost-Effective

Minimizes the financial risk of product development.

Flexibility

Allows for easy design modifications and iterations.

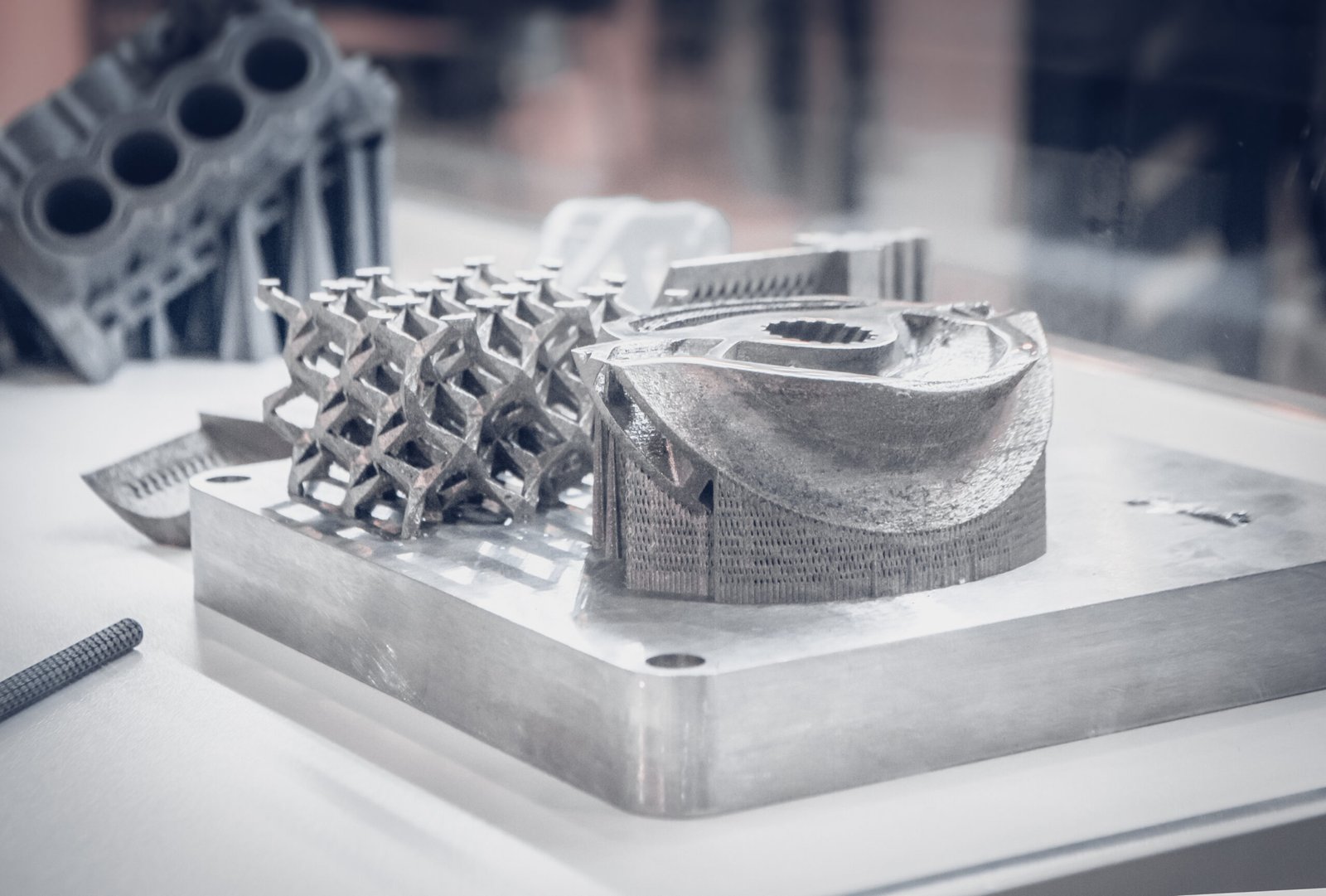

Realism

Produces accurate, functional prototypes for thorough testing.