Urethane Casting

Get a Quote

Have Questions? Get in touch and we will reach out shortly

What is Urethane Casting?

Urethane casting is an advanced manufacturing process used to produce high-quality prototypes and low-volume production parts. The process begins with creating a master model using 3D printing or CNC machining. A silicone mold is then made from this master model. Liquid resin is poured into the mold under vacuum conditions, ensuring that the final parts are free from air bubbles and have an impeccable surface finish.

The Benefits of Urethane Casting

When the customer needs to do injection molding, however, due to the limit of low demand needed and special geometry features, urethane casting could be a good solution. Urethane castings plays an important role and can provide many advantages over injection molding. In addition to the lower tooling cost, urethane casting have an extremely fast turnaround Compared to injection molding. What’s more, there are also many kinds of materials to choose from, Ranging from rigid and impact resistant to soft and flexible materials. Colors, textures, and finishes can also be achieved by urethane casting, including high-polished, transparent, grained, Painting, etc,.On the other hand, in a lot of instances, urethane casting parts have similar strength and durability properties to injection molding parts.

Our Urethane Casting Services:

- Rapid Prototyping

- Low Volume Production Runs

- Pre-Production Runs

- Test Samples

- Concept Model

- Automotive Parts

- Aircraft Interior Components

- Medical Devices

- Consumer Products

Urethane Casting Materials

ABS - Like

ABS - Like FR VO

ABS - Like HT

Acrylic - Like

Nylon - Like

Opaque Elastomer

POM - Like

PP -Like

Waterclear Elastomer

Urethane Casting Finishing Options

Matte

Glossy

Texture

Clear/Transparent

Semi-transparent

The process of Urethans Casting

Our customers from various industry such as electronics, consumer products, agriculture, automotive, robotic, etc.

Design and Master model

Make a master model by finalized CAD file, typically using stereolithography. Process the master model by sanding, priming and painting to have a smooth surface.

Silicone Mold

Suspend the master model in a box. Pour liquid silicone rubber around it. And then put it into an oven and cure it. After that, split it, open it up, finally take the master mold out . A core and cavity mold is finished.

Polyurethane

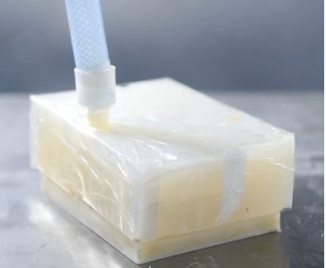

Mix up the materials and pour it into the mold. With enough time in oven and curing, the liquid polyurethane will be casted into the designed part.

Post-treatment

Trim the flashes and smooth the surface. Besides, additional surface finishing can be added including painting, logo printing and assembly for the casting parts.

Urethane Casting Services FAQs

Vacuum casting is a manufacturing process used to produce high-quality prototypes and small production runs. It involves creating a silicone mold from a master model and casting liquid resin into the mold under vacuum to ensure detailed and bubble-free parts.

Vacuum casting is ideal for producing detailed and functional prototypes, including complex geometries, intricate designs, and parts requiring high precision. It is also used for small-batch production runs where fine detail and surface finish are critical.

Common materials used in vacuum casting include various polyurethane resins, silicone rubbers, and other casting compounds. These materials can be selected based on the desired properties such as durability, flexibility, and appearance.

Vacuum casting provides high accuracy and detailed replication of the original master model. The use of silicone molds and vacuum conditions ensures that the final cast parts are precise and free from air bubbles, closely matching the original design.

The turnaround time for vacuum casting varies depending on the complexity of the part and the number of prototypes or production parts required. Generally, it is faster than traditional tooling methods, and we provide estimated timelines based on your project’s specifics.

Why Choose GREFIT

Unmatched Expertise and Innovative Solutions

A range of two-part polyurethanes can simulate the properties of common plastics such as ABS, nylon, and polypropylene, with options to enhance characteristics using additives like glass fibers.

Typically 7-14 days

With years of industry experience, our team brings extensive knowledge and skill to every project.

Flexibility for any project size

Achieve exact specifications with consistent accuracy for every part..

We utilize the latest advancements in technology and equipment

Affordable machining services without compromising on quality

Extensive range of materials, including metals, plastics, and composites, for versatile applications.

Thorough inspections and testing to ensure parts meet high standards.

Reliable service with a history of successful projects and satisfied clients.