The Values and Impact of Rapid Prototyping on Innovation and Different Industries

Introduction:

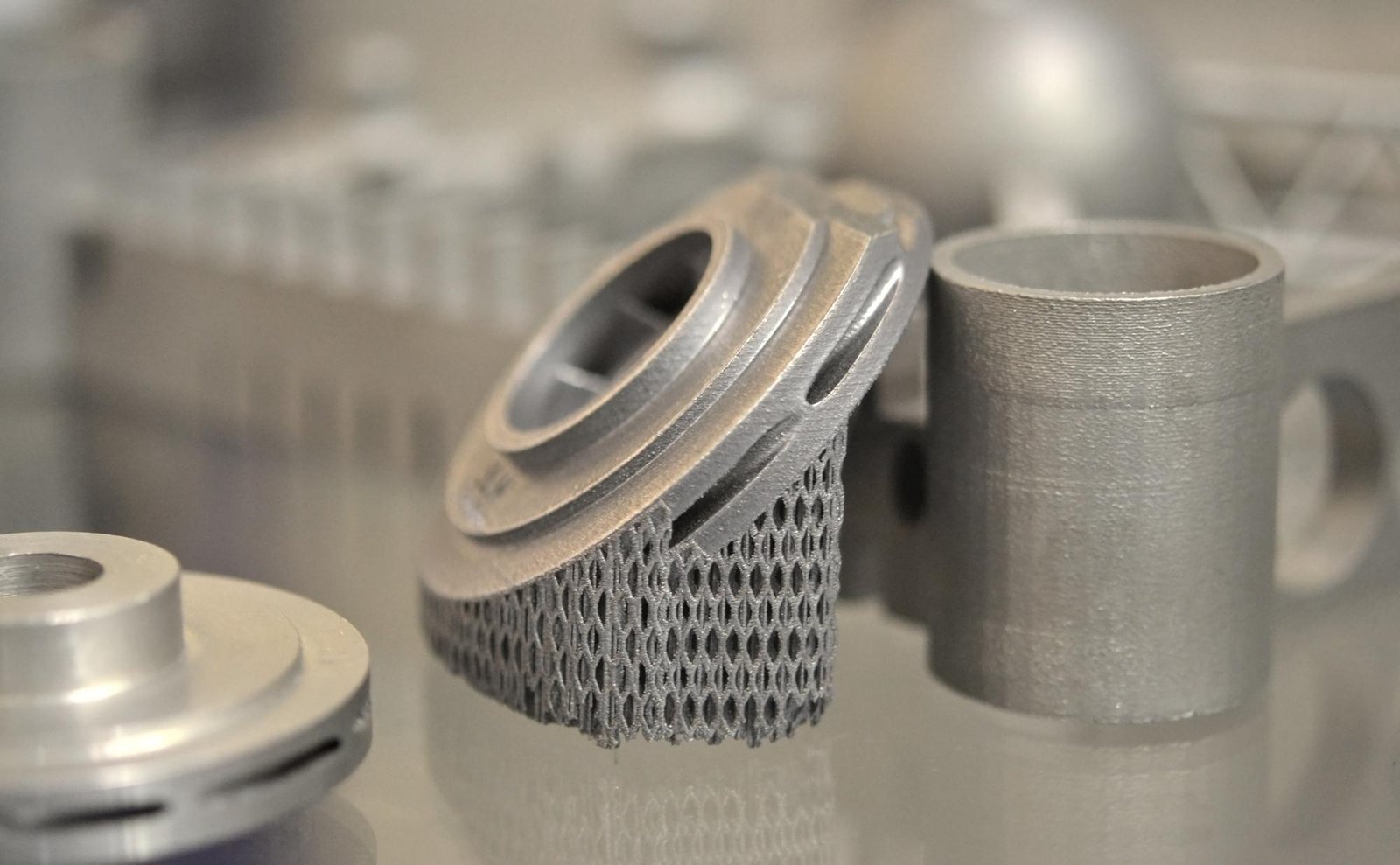

Rapid prototyping, an essential tool in modern manufacturing, significantly impacts innovation and various industries. It involves quickly fabricating a scale model or part using 3D printing or other advanced technologies. This process is transforming how businesses approach design and development, offering speed, flexibility, and efficiency.

Driving Innovation:

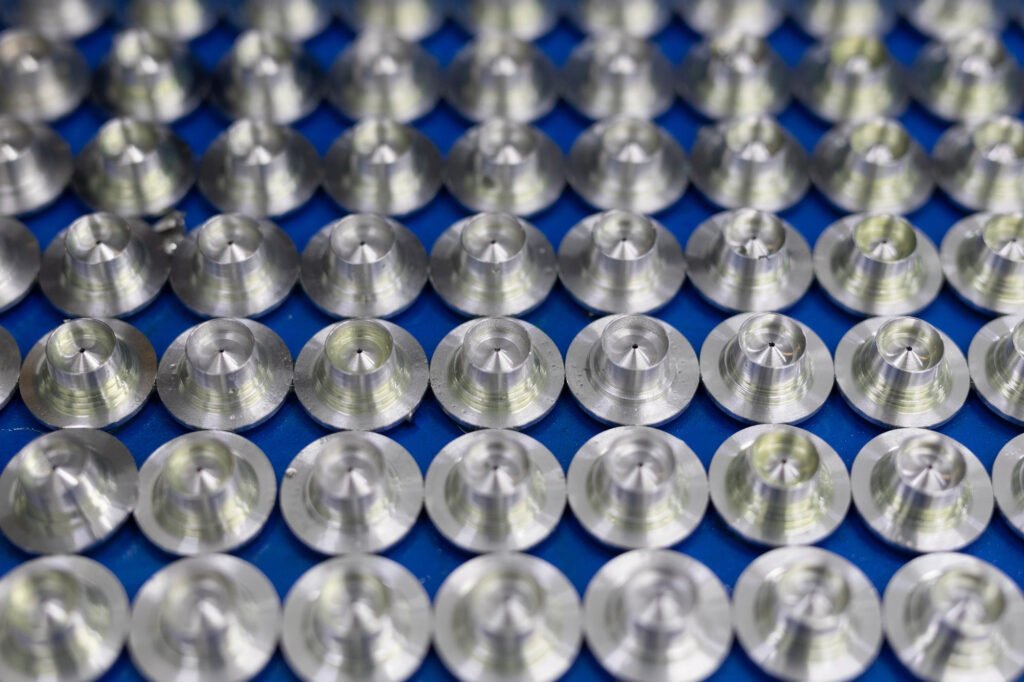

Innovation thrives when ideas can be tested and iterated quickly. Rapid prototyping allows for the swift transition from concept to physical model, enabling designers and engineers to identify potential issues early. This iterative process accelerates product development, leading to more refined and innovative final products. By reducing the time between design iterations, companies can experiment with bolder ideas and refine them with less risk and cost.

Impact on Different Industries:

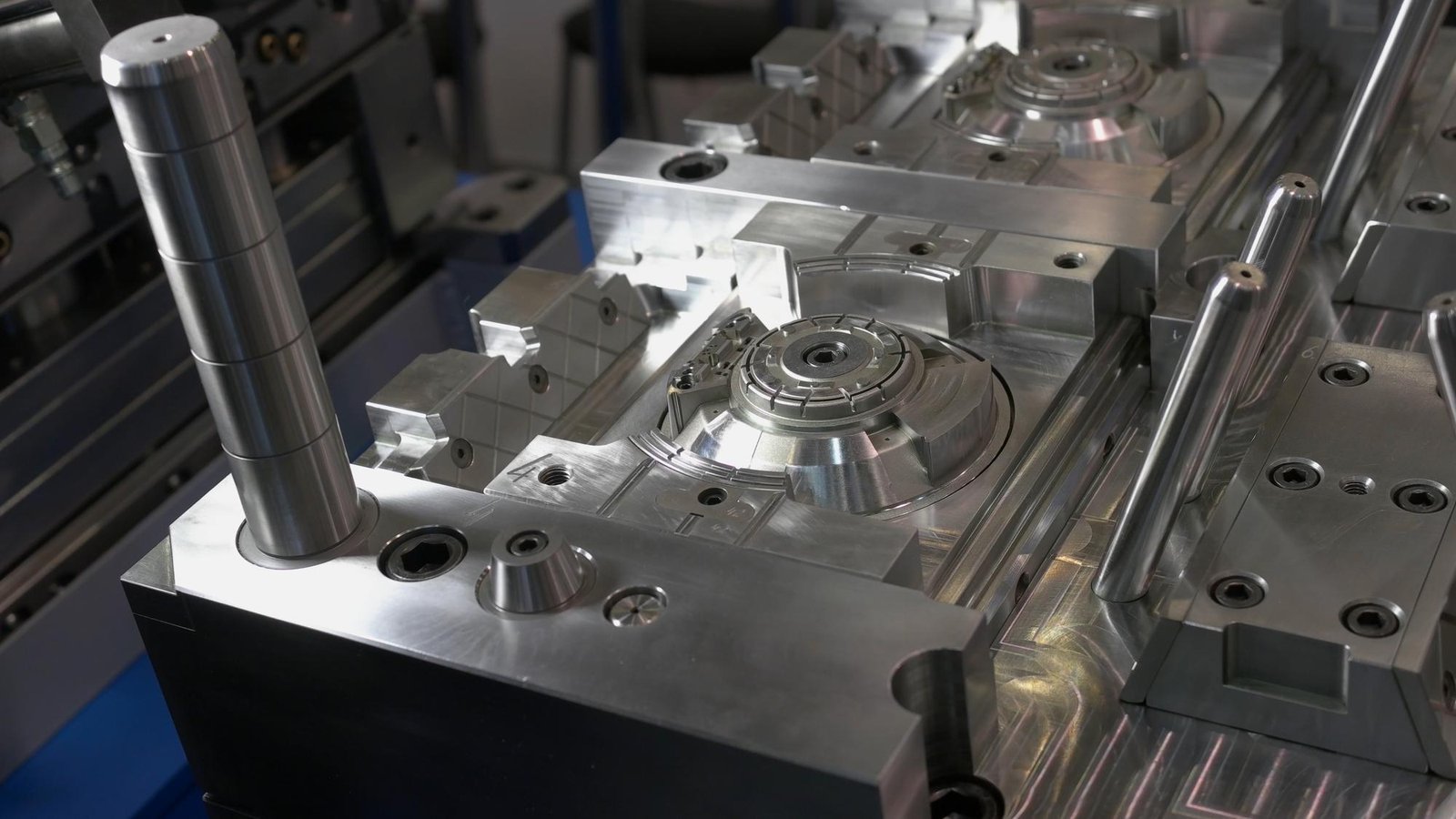

- Automotive Industry: In the automotive sector, rapid prototyping is used to create parts and components for testing, reducing development cycles and improving design accuracy. It enables automakers to innovate continuously, responding to consumer demands and technological advancements quickly.

- Healthcare: In healthcare, rapid prototyping is revolutionizing medical devices and personalized healthcare solutions. Surgeons can create models of organs for pre-surgical planning, and custom prosthetics can be developed to fit patients perfectly.

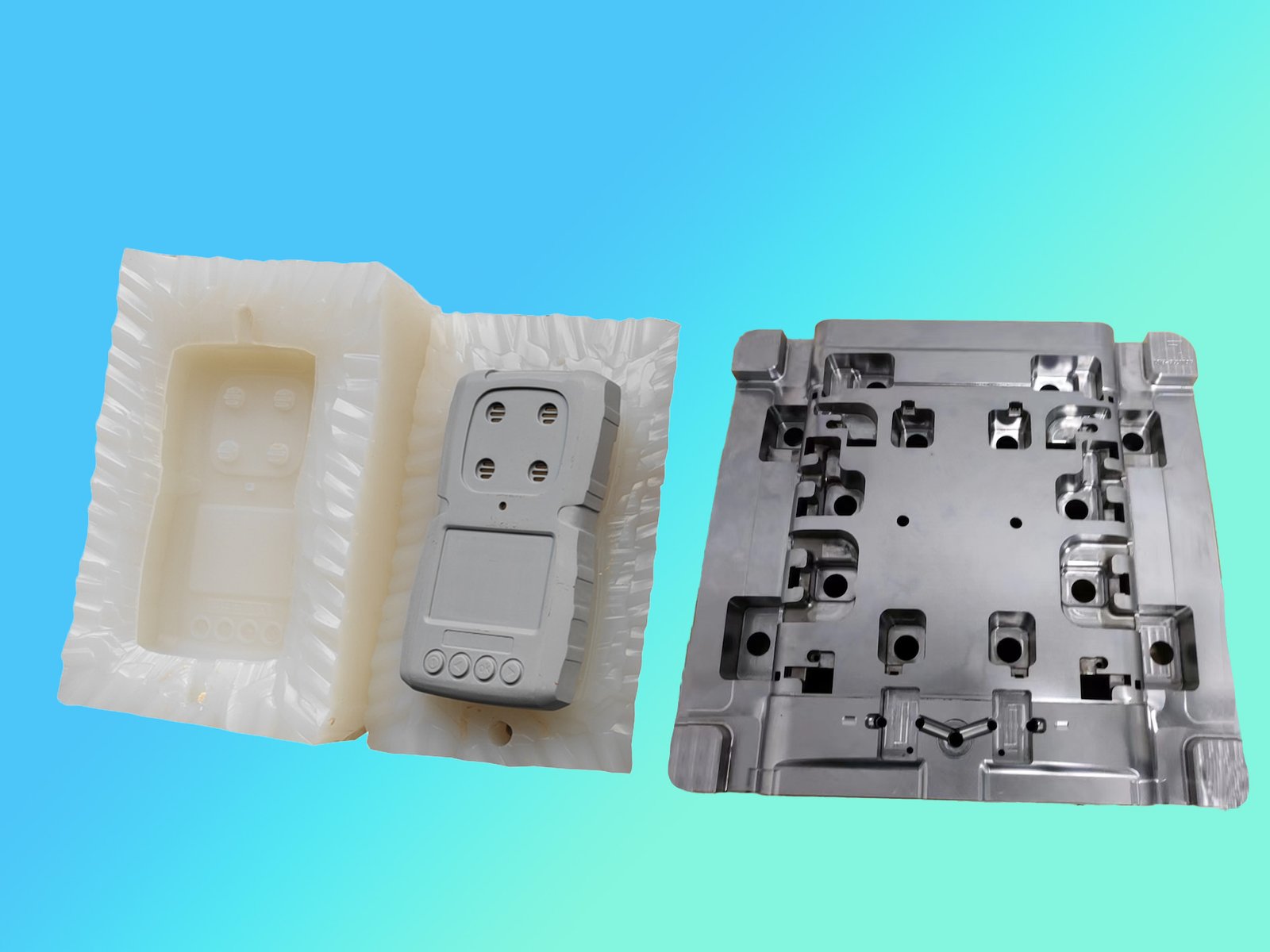

- Consumer Electronics: The consumer electronics industry benefits from rapid prototyping by accelerating the development of new gadgets and devices. Companies can test multiple designs simultaneously, ensuring that the final product meets consumer expectations.

- Aerospace: In aerospace, rapid prototyping helps in the development of complex parts and components. The ability to produce and test parts quickly ensures that safety and performance standards are met without extended development times.

Economic Efficiency:

Rapid prototyping reduces the costs associated with traditional manufacturing methods. By identifying design flaws early, companies can avoid expensive modifications later in the production process. Additionally, the ability to produce low-volume prototypes on demand minimizes waste and lowers material costs.

Conclusion:

Rapid prototyping is a powerful tool that drives innovation across multiple industries. Its ability to accelerate product development, reduce costs, and enhance design flexibility makes it indispensable in today’s fast-paced market. As technology continues to advance, the impact of rapid prototyping on innovation will only grow, enabling companies to push the boundaries of what’s possible.