3D printing, also known as additive manufacturing, has profoundly impacted various industries by offering unique advantages in design, production, and innovation. Here’s how it shapes the industrial landscape:

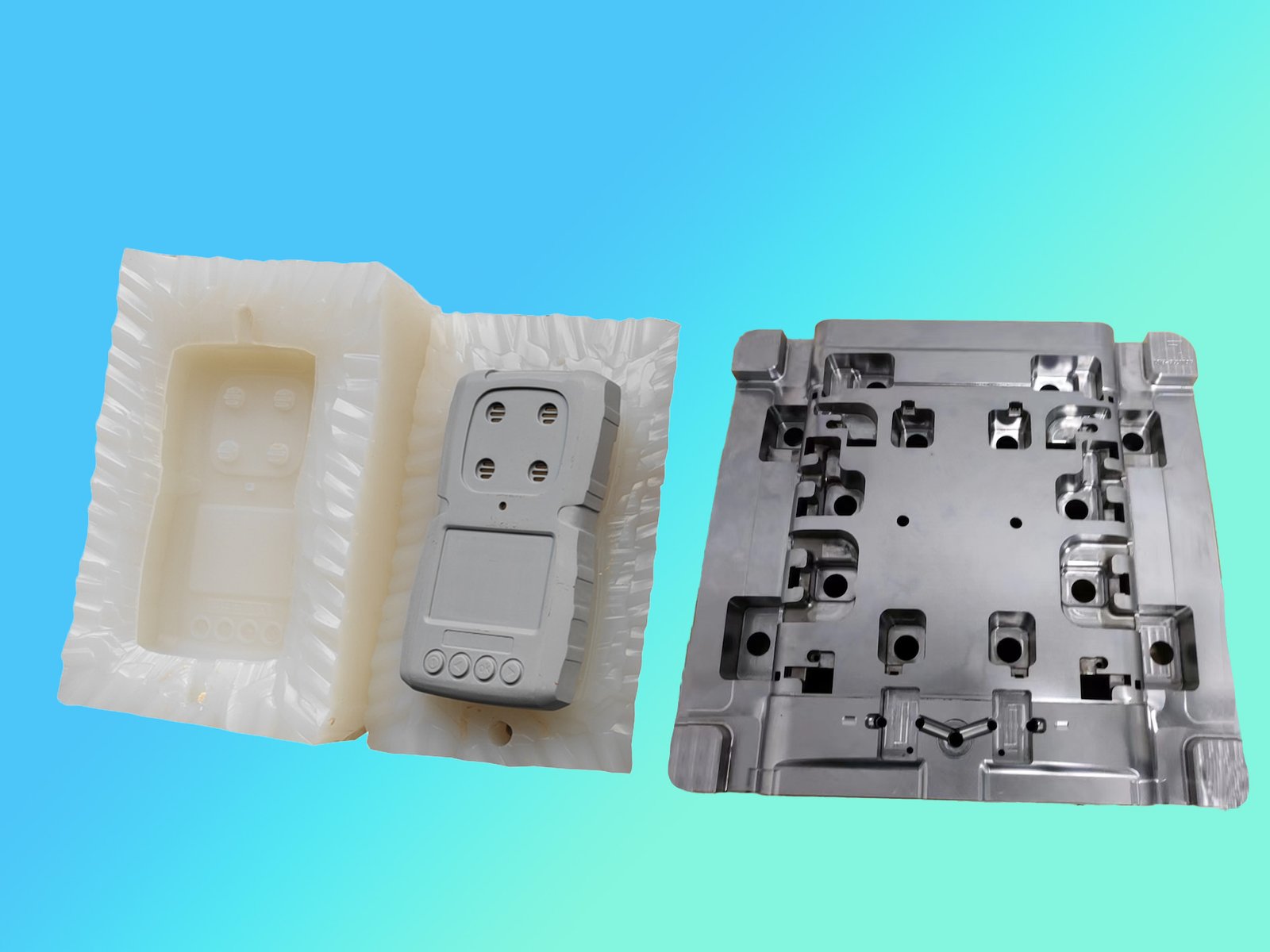

1. Rapid Prototyping:

3D printing allows companies to create prototypes quickly and cost-effectively. This accelerates the design process, enabling faster iterations and reducing time to market.

2. Customization:

Industries such as healthcare, automotive, and aerospace benefit from 3D printing’s ability to produce highly customized parts. Whether it’s personalized medical implants or tailored car components, 3D printing enables bespoke solutions without the need for expensive tooling.

3. Reduced Waste:

Unlike traditional subtractive manufacturing, where excess material is removed from a larger block, 3D printing builds parts layer by layer, resulting in minimal waste. This efficiency not only conserves resources but also supports sustainable manufacturing practices.

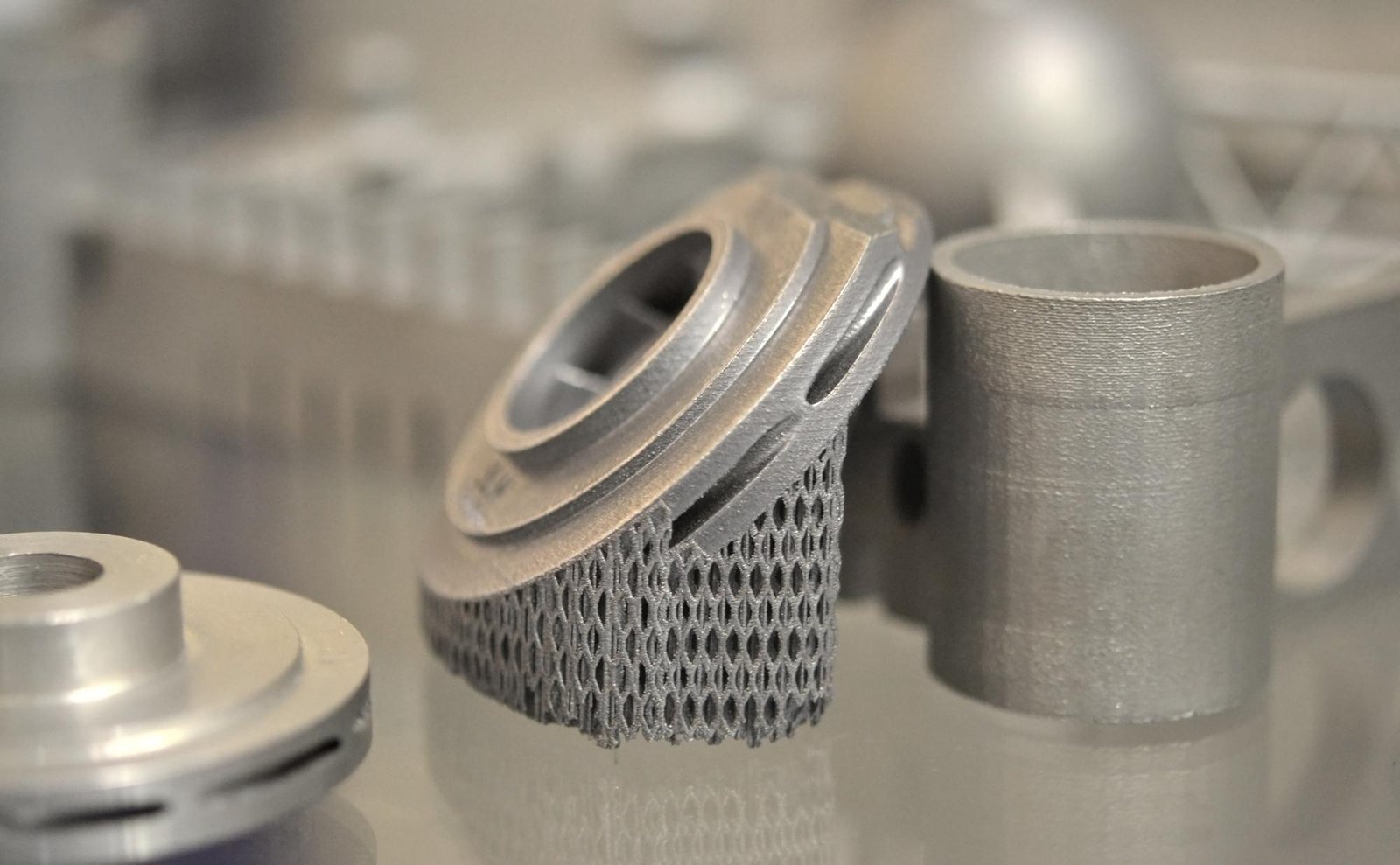

4. Complex Geometries:

3D printing can produce intricate designs that would be impossible or costly to achieve with conventional methods. This capability opens new possibilities for innovation, allowing industries to push the boundaries of what’s possible in design and engineering.

5. Supply Chain Flexibility:

By enabling on-demand production, 3D printing reduces the need for large inventories and allows for more localized manufacturing. This flexibility can reduce lead times, shipping costs, and dependence on distant suppliers, making supply chains more resilient.

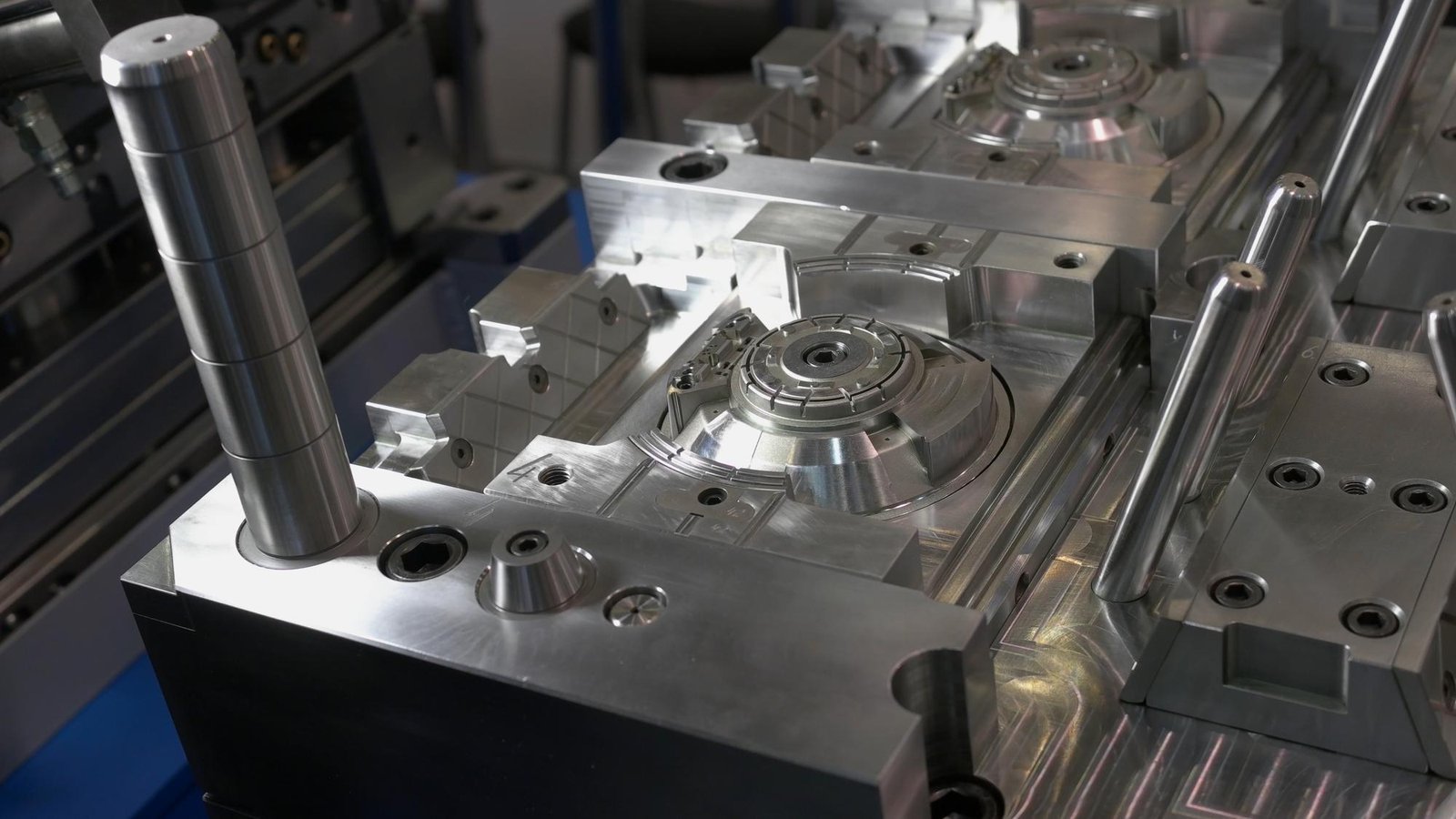

6. Cost Efficiency for Low-Volume Production:

For industries that require small production runs, such as aerospace or niche consumer products, 3D printing offers a cost-effective solution. It eliminates the need for expensive molds and tooling, making it an economical choice for limited production quantities.

7. Innovation in Materials:

The development of new materials specifically designed for 3D printing has broadened its application across various industries. From high-strength polymers to metal alloys, these advanced materials enable the production of durable, functional parts that meet industry-specific standards.

8. Impact on Healthcare:

In healthcare, 3D printing has enabled the creation of customized implants, prosthetics, and even bioprinted tissues. This technology allows for personalized medical treatments, improving patient outcomes and advancing medical research.

Conclusion

3D printing is reshaping industries by enabling faster, more efficient, and highly customizable manufacturing. Its impact spans from rapid prototyping to sustainable production, offering companies new ways to innovate and meet the demands of an ever-changing market. At Grefit Prototype, we harness the power of 3D printing to deliver cutting-edge solutions that drive success across various sectors. Whether you’re looking to prototype a new design or produce a customized part, our 3D printing services are here to help you achieve your goals.