The process of Plastic Injection Molding

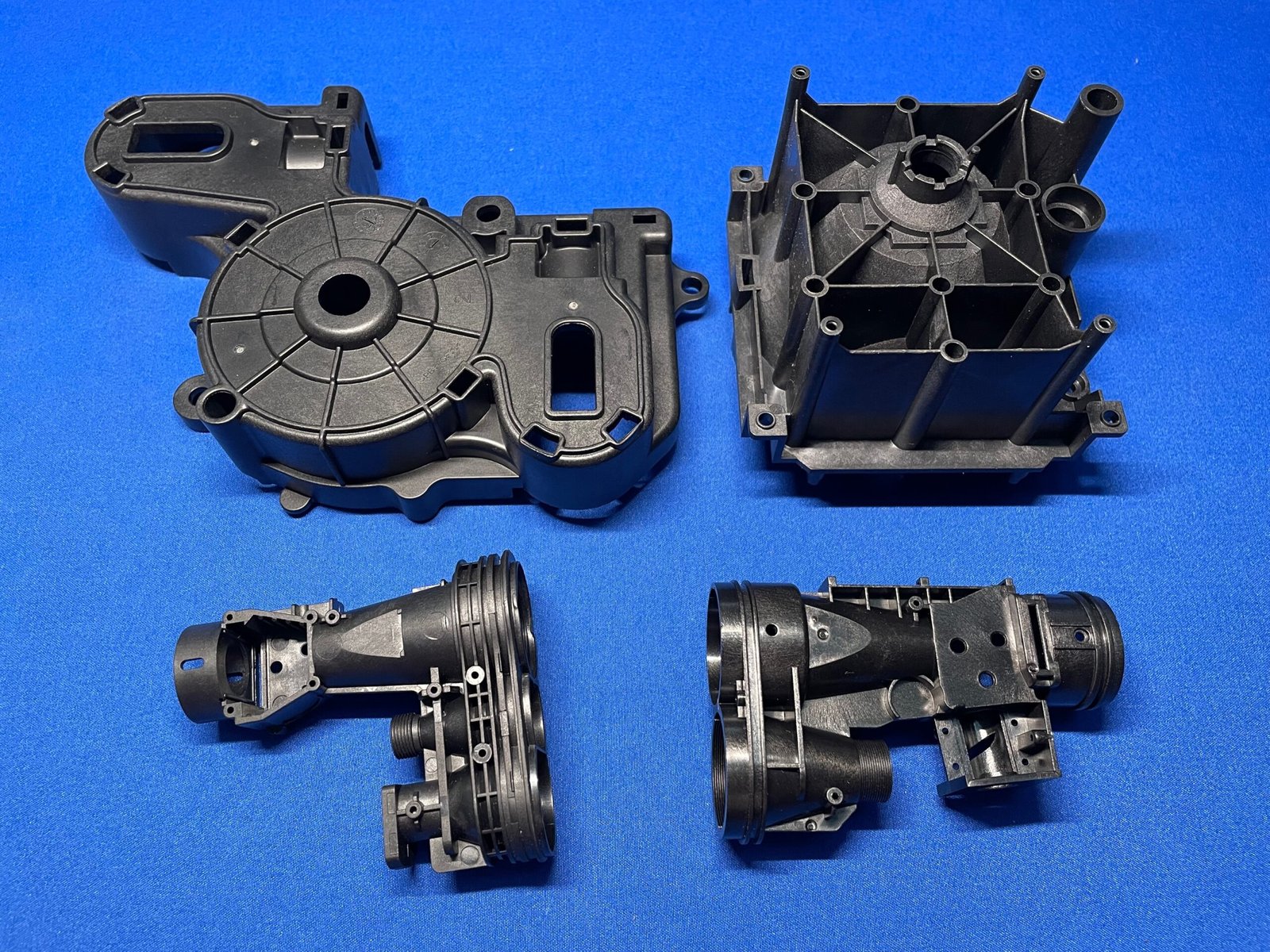

Our customers from various industry such as electronics, consumer products, agriculture, automotive, robotic, etc.

Machine Tonnage

The powered clamping unit pushes the mold halves close and exerts sufficient force to keep the mold securely closed while the liquid resin material gets injected into the mold cavities. We have to determine the right machine tonnage to ensure enough clamping force.

Raw Material

Drying plastic pellets before feeding into the hopper that is connected to the injection molding machine. When there is a need for colors, we can do pre-color or add the pigments for injection molding.

Injection Phase

The pellets get heated and melted in the barrel. Once the material is melted, the screw moves forward, injecting molten resin into the mold with a high pressure. For accurate melt temperatures, a combination of settings needs to be considered and applied, including the temperature of barrel, nozzle, and injection mold.

Cooling

Cooling of the molten resin inside the mold cavities will solidify into the shape of the part. Cooling system is considered when doing the injection mold design. The part and mold designs, as well as the resin raw material used, helps determine the cooling times.

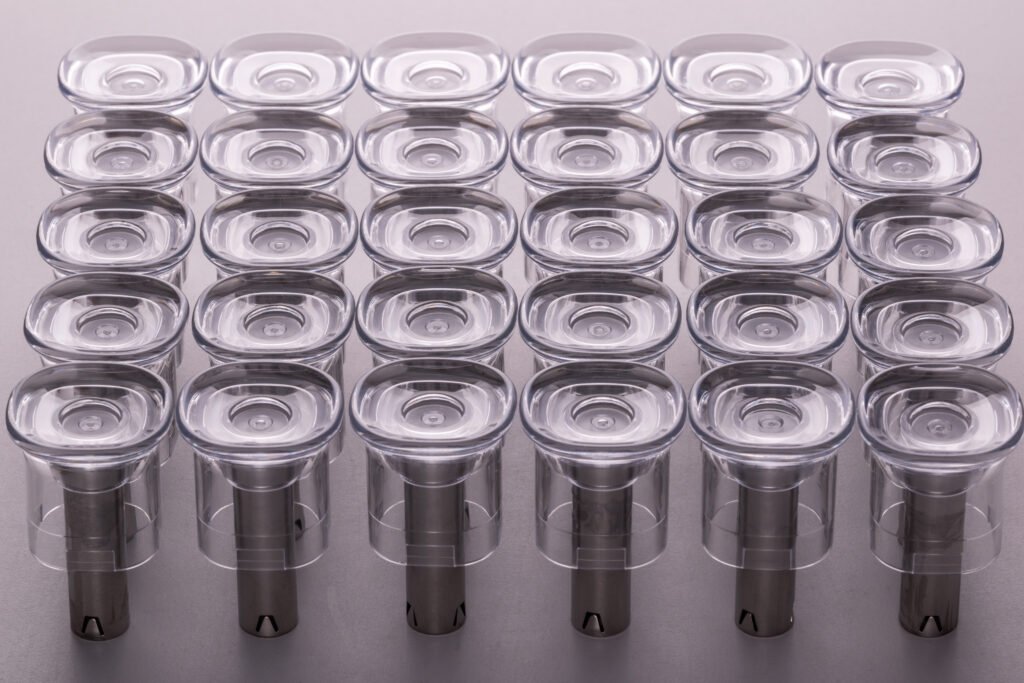

Ejection of plastic part

When the clamping unit opens the injection mold, an ejection pin/block pushes the part out of the mold. During the cooling process, the component shrinks and adheres to the mold cavities requiring force to eject the part.

Post Treatment

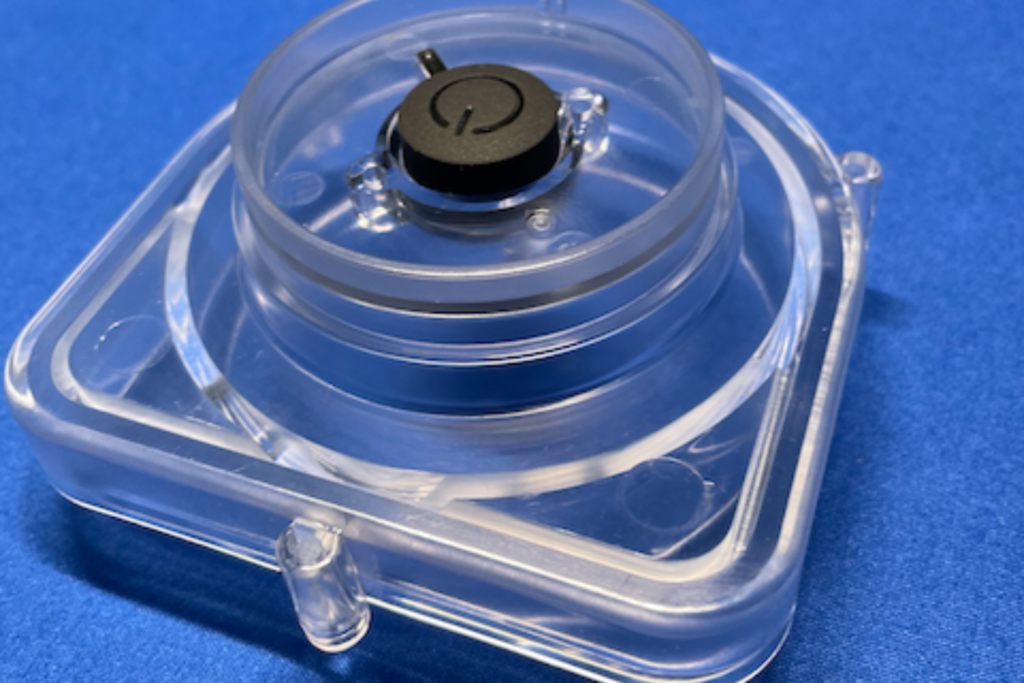

The part may require additional finishing processes, such as trimming, painting, Logo printing, electric plating or assembly.