Expert Analysis

Our skilled inspectors use their expertise to identify even the smallest defects, ensuring your products meet the highest quality standards.

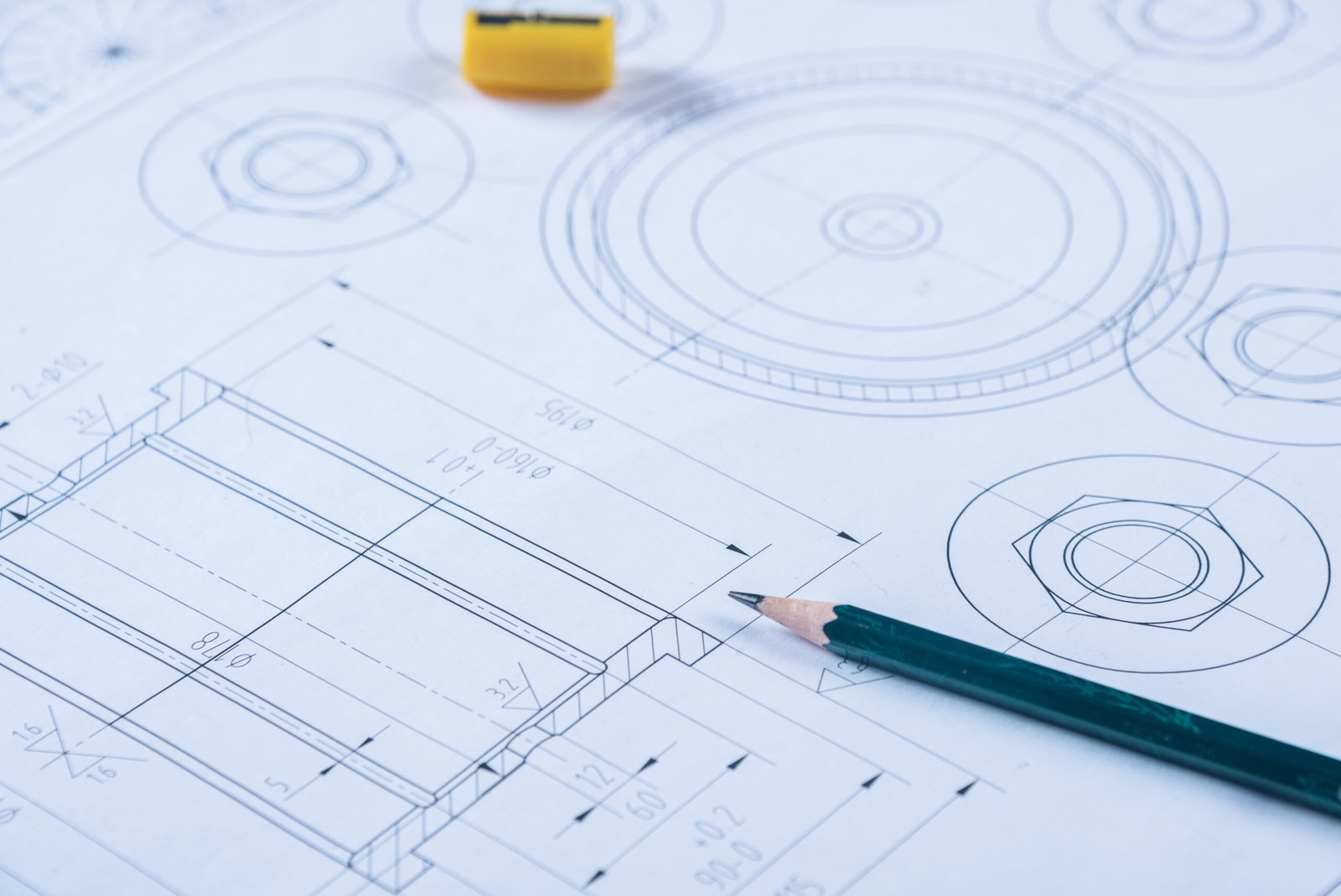

Advanced Technology

We employ the latest inspection tools and equipment to provide precise measurements and detailed evaluations.

Comprehensive Coverage

Our inspection services include dimensional, visual, functional, and material testing, ensuring all aspects of your products are thoroughly checked.

Quality Assurance

We are committed to maintaining stringent quality control, ensuring that every product meets or exceeds your specifications and industry standards.