Sheet Metal

Get a Quote

Have Questions? Get in touch and we will reach out shortly

Sheet Metal

At Grefit Prototype, we offer comprehensive sheet metal services designed to meet a diverse array of industrial and commercial needs. Our expertise in sheet metal fabrication ensures that every project, whether large or small, is executed with precision, efficiency, and quality.

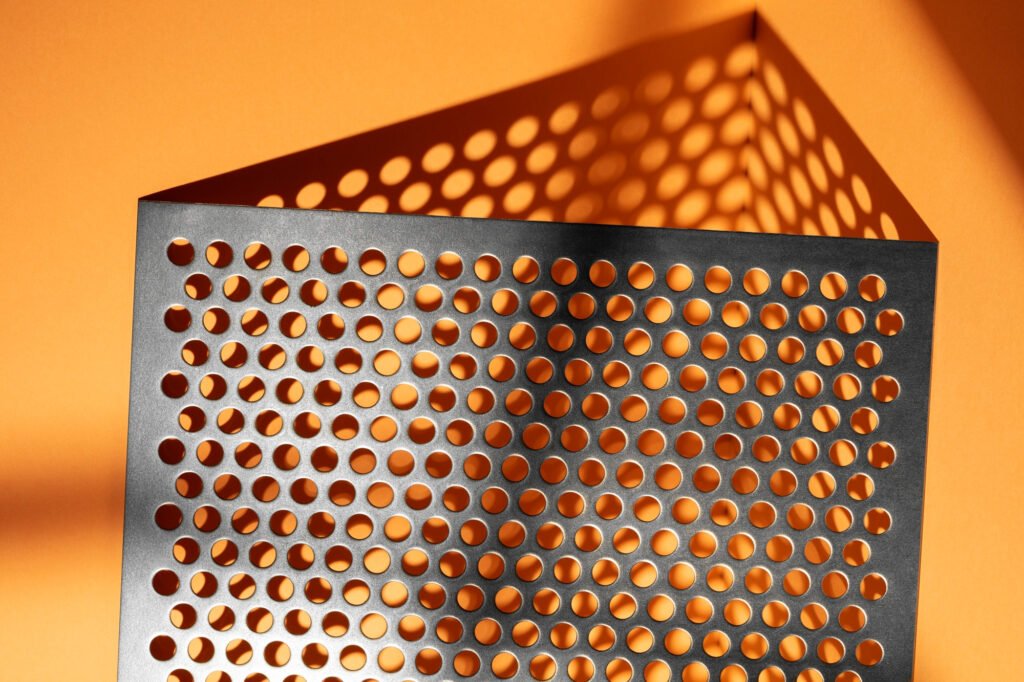

Precision and Versatility

Our sheet metal services are characterized by precision and versatility. We handle various processes including cutting, bending, and finishing to create components that meet stringent specifications. Our state-of-the-art equipment and experienced technicians work together to ensure that each part is produced with exacting accuracy and attention to detail.

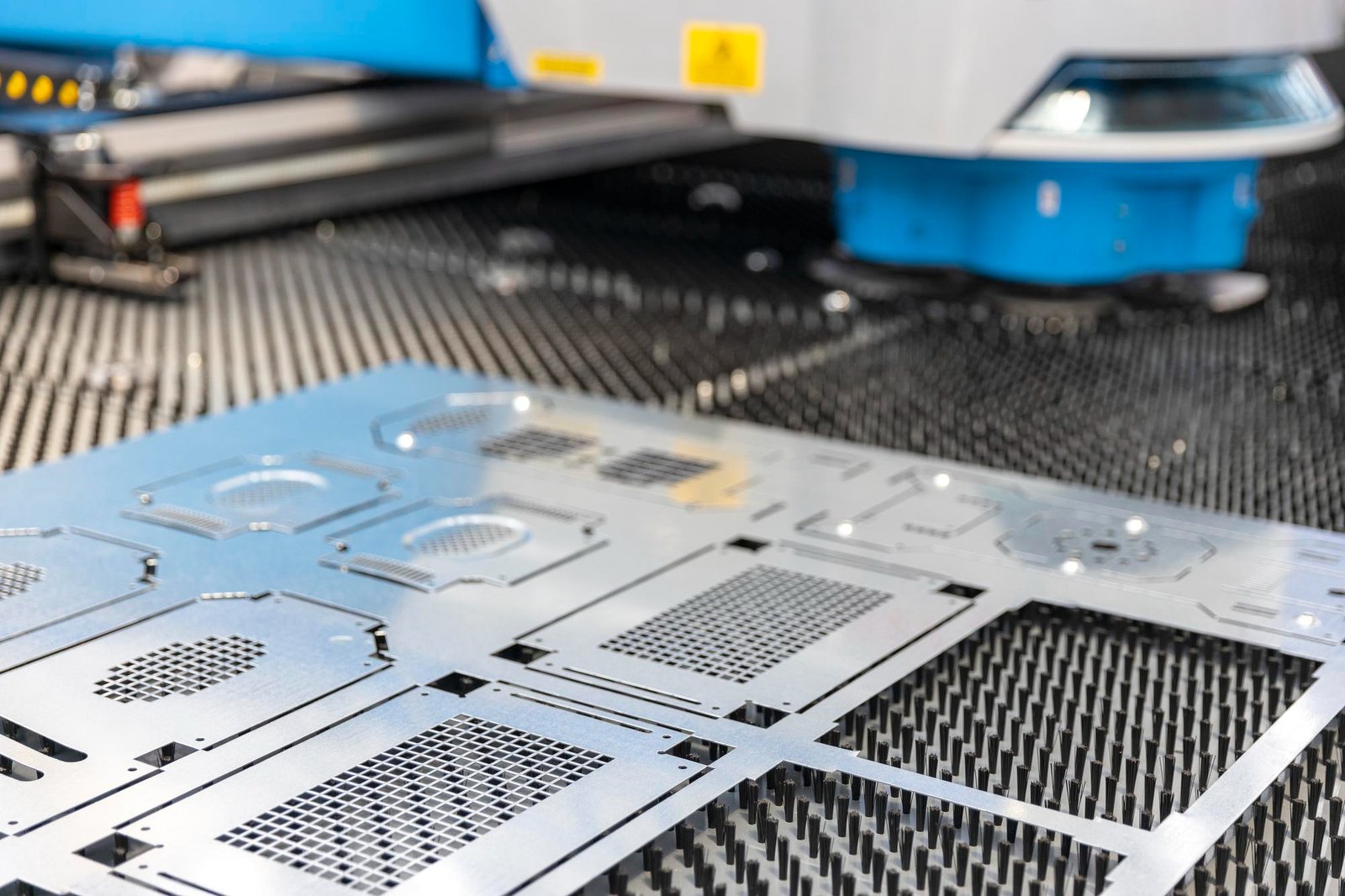

Cutting

The cutting process is a crucial first step in sheet metal fabrication. At Grefit Prototype, we use advanced cutting technologies such as laser cutting and waterjet cutting to achieve clean, precise cuts on a range of metal types. Laser cutting is particularly effective for intricate designs and tight tolerances, while waterjet cutting is ideal for thicker materials and complex shapes. Our cutting services ensure that your components are accurately shaped and ready for further processing.

Bending

Once the metal is cut, the bending process transforms flat sheets into three-dimensional parts. Our bending capabilities include both manual and automated methods to handle various material thicknesses and shapes. Using press brakes and other advanced equipment, we can achieve precise angles and curves to meet your design requirements. Whether you need simple bends or complex forms, our skilled technicians ensure that each part maintains its structural integrity and dimensional accuracy.

Finishing

Finishing is an essential step to enhance the appearance and performance of sheet metal components. At Grefit Prototype, we offer a range of finishing services including powder coating, anodizing, and plating. Powder coating provides a durable, corrosion-resistant finish in a variety of colors, while anodizing enhances aluminum components with a protective oxide layer. Plating options such as zinc or nickel plating add additional protection and aesthetic appeal. Our finishing services not only improve the look of your parts but also extend their lifespan and functionality.

Assembly

Our sheet metal services extend to assembly, ensuring that your components are fully integrated and functional upon delivery. We offer assembly services that include welding, riveting, and fastening. Whether your project requires simple joins or complex assemblies, our team employs precision techniques and high-quality materials to ensure that each component fits together seamlessly and performs as intended.

Custom Prototypes and Production Runs

At Grefit Prototype, we cater to both custom prototypes and large-scale production runs. Our flexible approach allows us to adapt to your specific needs, whether you require a single prototype for testing and validation or a full production run for commercial use. We work closely with you throughout the development process to ensure that each part meets your exact specifications and quality standards.

Quality Control

Quality control is at the heart of our sheet metal services. We implement rigorous testing and inspection procedures to ensure that every component meets industry standards and your precise requirements. Our quality assurance process includes dimensional checks, material testing, and visual inspections to identify and address any potential issues before your parts are delivered.

Sustainability

We are committed to sustainability and environmental responsibility in our sheet metal fabrication processes. At Grefit Prototype, we prioritize the use of recyclable materials and implement waste reduction practices to minimize our environmental impact. By optimizing our processes and adopting green technologies, we strive to contribute to a more sustainable future while delivering high-quality products.

Customer Collaboration

Collaboration with our clients is a key element of our service. We understand that each project is unique, and we work closely with you to understand your specific needs and goals. Our team of experts provides guidance and support throughout the fabrication process, from initial design and material selection to final production and delivery. Your satisfaction is our top priority, and we are dedicated to providing solutions that exceed your expectations.

Advanced Technology

Grefit Prototype invests in cutting-edge technology to enhance our sheet metal services. Our facility is equipped with the latest machinery and software to support advanced fabrication techniques and improve efficiency. By leveraging technology, we can offer enhanced capabilities, faster turnaround times, and superior precision in all our sheet metal projects.

Conclusion

Whether you need custom prototypes, large production runs, or intricate sheet metal components, Grefit Prototype is your trusted partner for precision and quality. Our comprehensive sheet metal services cover every aspect of the fabrication process, ensuring that your components are produced to the highest standards. Contact us today to discuss your project requirements and discover how our expertise can help you achieve your goals.

The Process of Sheet Metal Services

Our customers from various industry such as electronics, consumer products, agriculture, automotive, robotic, etc.

Design and Material Selection

Share your design specifications, and we will assist in selecting the appropriate type of sheet metal, ensuring it fits your project requirements for strength, durability, and functionality.

Precision Fabrication

Using advanced sheet metal fabrication techniques, we cut, bend, and shape the material to meet your design specifications. Our process guarantees precision and consistency for projects of any size.

Assembly and Finishing

After fabrication, we assemble and apply any necessary surface treatments or finishes. This step ensures that your sheet metal components not only perform well but also meet aesthetic and protective requirements.

Final Quality Check and Delivery

Each part is thoroughly inspected for quality and accuracy before being packaged and delivered. We ensure that your sheet metal components are ready for immediate use in your project.

Sheet Metal Services FAQs

At Grefit Prototype, we offer a full range of sheet metal fabrication services, including cutting, bending, stamping, welding, and assembly. Our comprehensive services are tailored to meet the specific needs of each project, whether for industrial or commercial applications.

Our sheet metal services cater to a variety of industries, including automotive, aerospace, construction, electronics, and more. We provide customized solutions to meet the unique requirements of each industry, ensuring high-quality and precise results.

We work with a wide range of metals, including aluminum, steel, stainless steel, copper, and brass. Our expertise in handling various materials ensures that we can deliver durable and reliable components, regardless of the project's specifications.

At Grefit Prototype, we utilize advanced fabrication techniques and state-of-the-art equipment to ensure precision and quality in every sheet metal project. Our skilled team closely monitors every step of the process to meet exacting standards, whether for small-scale prototypes or large production runs.

Yes, we have the capability to manage projects of all sizes. Whether it's a small prototype or a large-scale production run, we ensure each project is executed with the same level of attention to detail, efficiency, and quality to meet your needs.

Why Choose Us

Unmatched Expertise and Innovative Solutions

At Grefit Prototype, we are dedicated to delivering excellence in every aspect of our work. Here’s why you should choose us for your prototyping and manufacturing needs

We leverage cutting-edge technology to solve complex manufacturing challenges.

Our skilled machinists and engineers ensure top-notch quality and craftsmanship.

Tailored CNC machining services to meet your unique project needs.

Achieve exact specifications with consistent accuracy for every part..

Capable of adapting to changing project needs and production scales.

Affordable machining services without compromising on quality

Extensive range of materials, including metals, plastics, and composites, for versatile applications.

Reliable and timely delivery to keep your projects on track

Reliable service with a history of successful projects and satisfied clients.