The Process of Surface Finishing

Our customers from various industry such as electronics, consumer products, agriculture, automotive, robotic, etc.

Assessment and Selection

We start by evaluating your component's material and application needs. Based on this assessment, we recommend the most suitable surface finishing techniques to enhance durability, appearance, and performance.

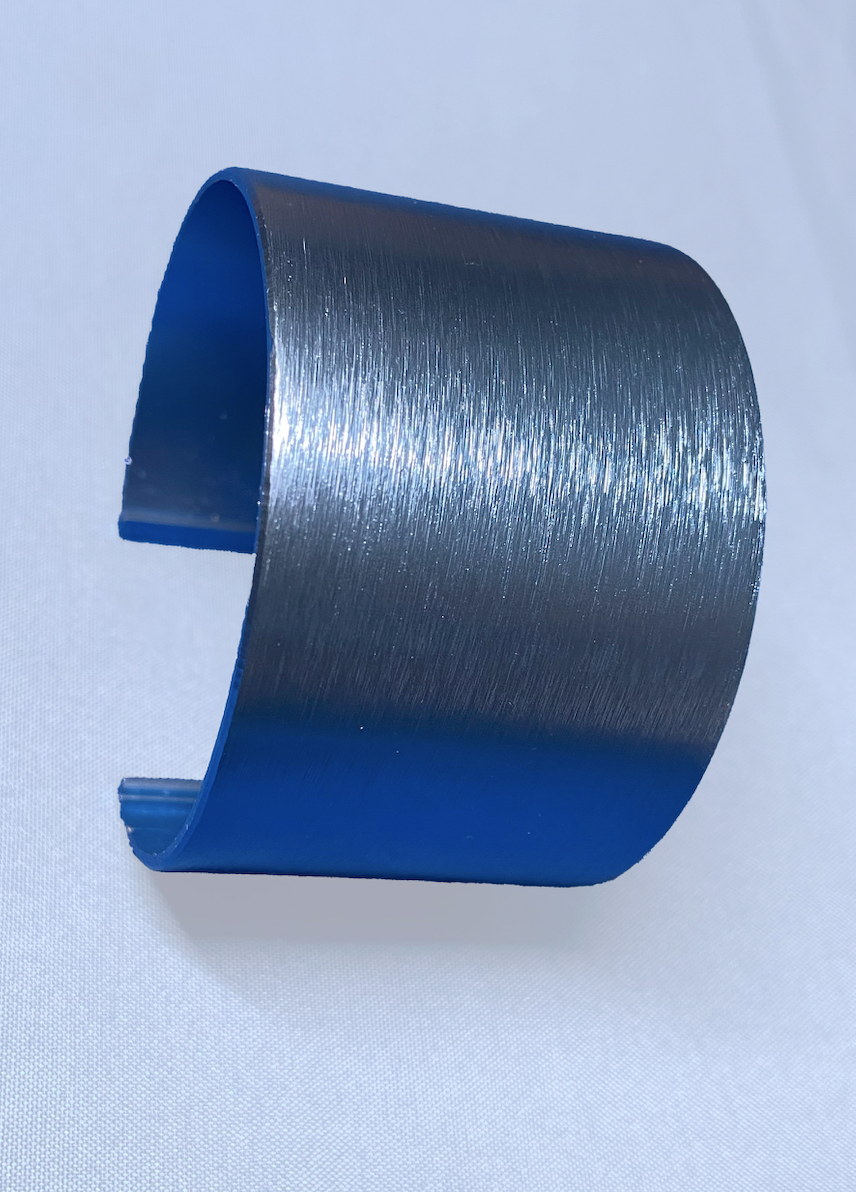

Preparation and Finishing Process

Once the appropriate finishing method is selected, we prepare the component by cleaning and pre-treating the surface. Our advanced finishing techniques, such as polishing, coating, or texturing, are then applied to achieve the desired result.

Quality Inspection

After finishing, each component undergoes a thorough inspection to ensure the finish meets your exact specifications. We check for consistency, durability, and appearance to ensure the highest quality.

Final Packaging and Delivery

Once the quality check is completed, the finished components are carefully packaged and delivered, ready for immediate use in your project, with enhanced performance and aesthetics.