The Development Trends for Tooling Design and Manufacturing

Introduction:

Tooling design and manufacturing are undergoing significant advancements driven by technological innovations, industry demands, and environmental considerations. These trends are reshaping how tools are designed, produced, and utilized across various sectors.

Key Trends:

- Automation and Smart Manufacturing:

- Automation is becoming central to tooling design and manufacturing, integrating robotics, AI, and IoT. Smart manufacturing systems enable real-time monitoring, predictive maintenance, and autonomous operations, leading to higher efficiency, reduced downtime, and better-quality control.

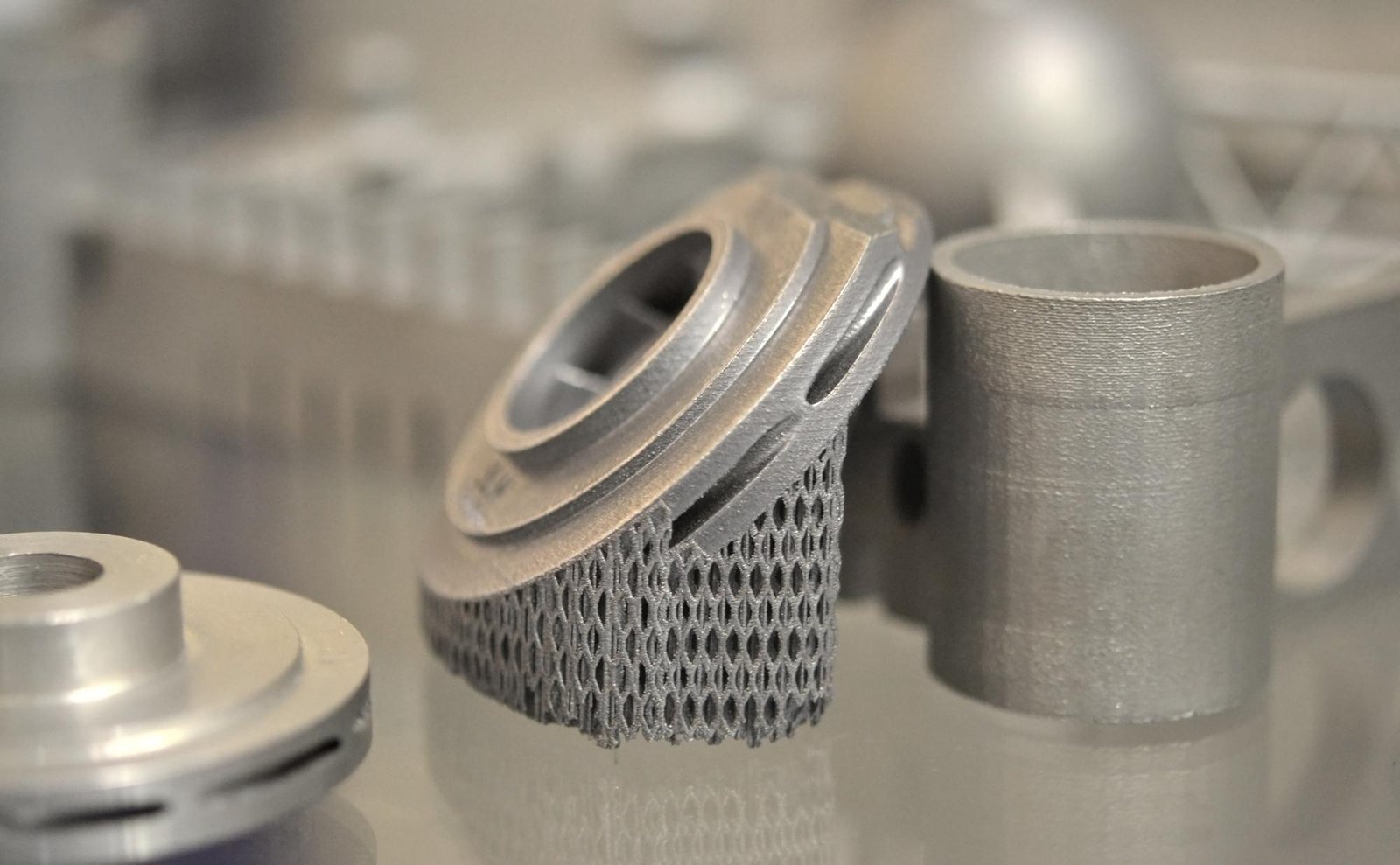

- Additive Manufacturing Integration:

- Additive manufacturing (3D printing) is increasingly used for producing tooling components, allowing for complex designs and rapid prototyping. This trend reduces lead times, lowers costs, and enables customization, particularly in low-volume production.

- Sustainability and Eco-friendly Practices:

- Environmental concerns are pushing the industry towards sustainable practices. This includes using recyclable materials, reducing waste, and designing tools that require less energy in production and operation. Eco-friendly tooling not only meets regulatory requirements but also appeals to environmentally conscious consumers.

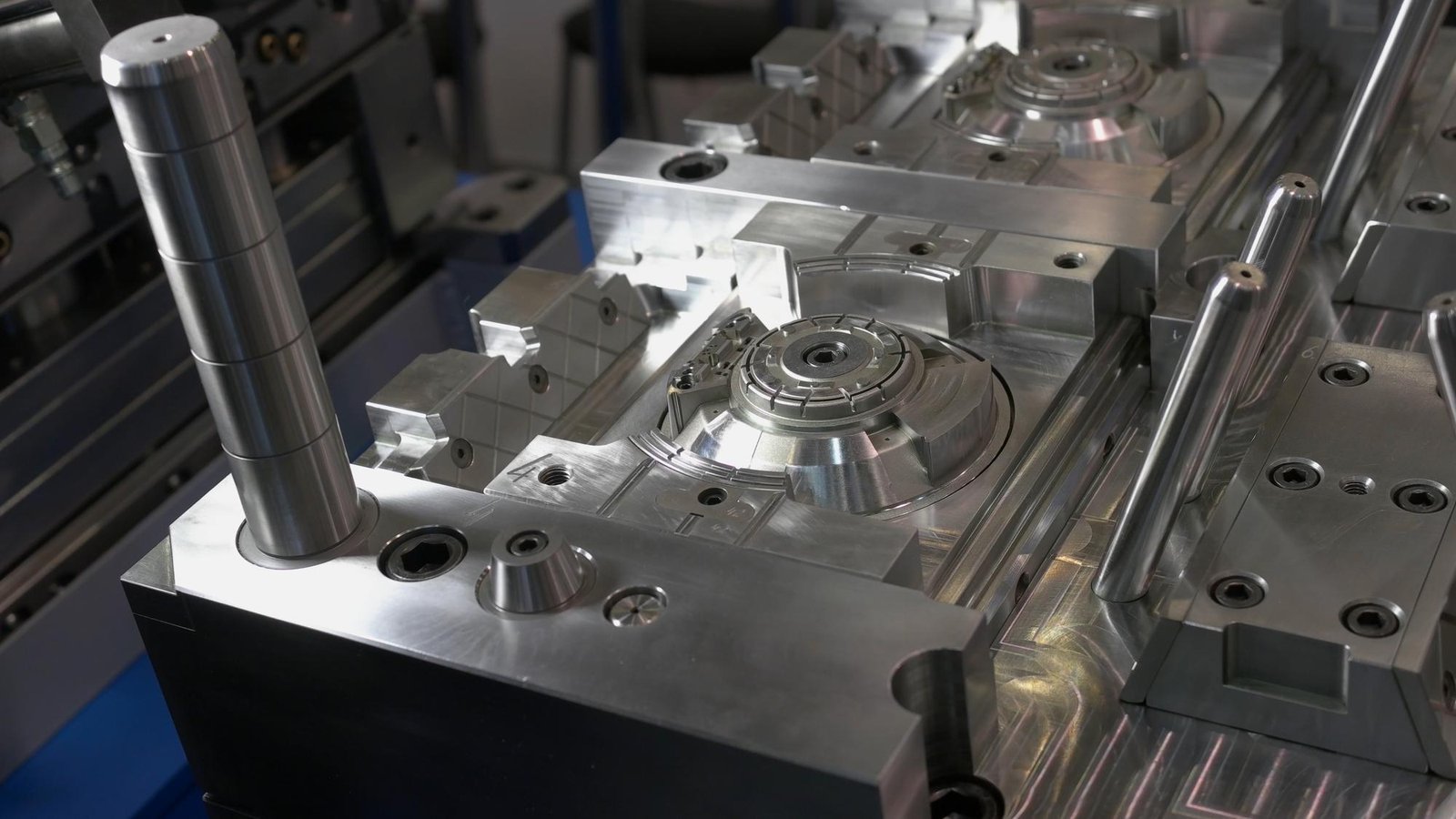

- Advanced Materials:

- The development of new materials, such as high-strength alloys, composites, and ceramics, is enhancing the performance and durability of tooling. These materials offer better resistance to wear, heat, and corrosion, extending tool life and improving productivity.

- Digital Twins and Simulation:

- The use of digital twins and simulation tools is becoming more prevalent in tooling design. These technologies allow designers to create virtual models of tools, simulate their performance under various conditions, and optimize designs before physical production. This reduces the risk of errors and accelerates the development process.

- Collaborative Design Platforms:

- Collaborative platforms and cloud-based design tools are enabling global teams to work together seamlessly on tooling projects. This trend fosters innovation by allowing experts from different disciplines and locations to contribute to the design process in real time.

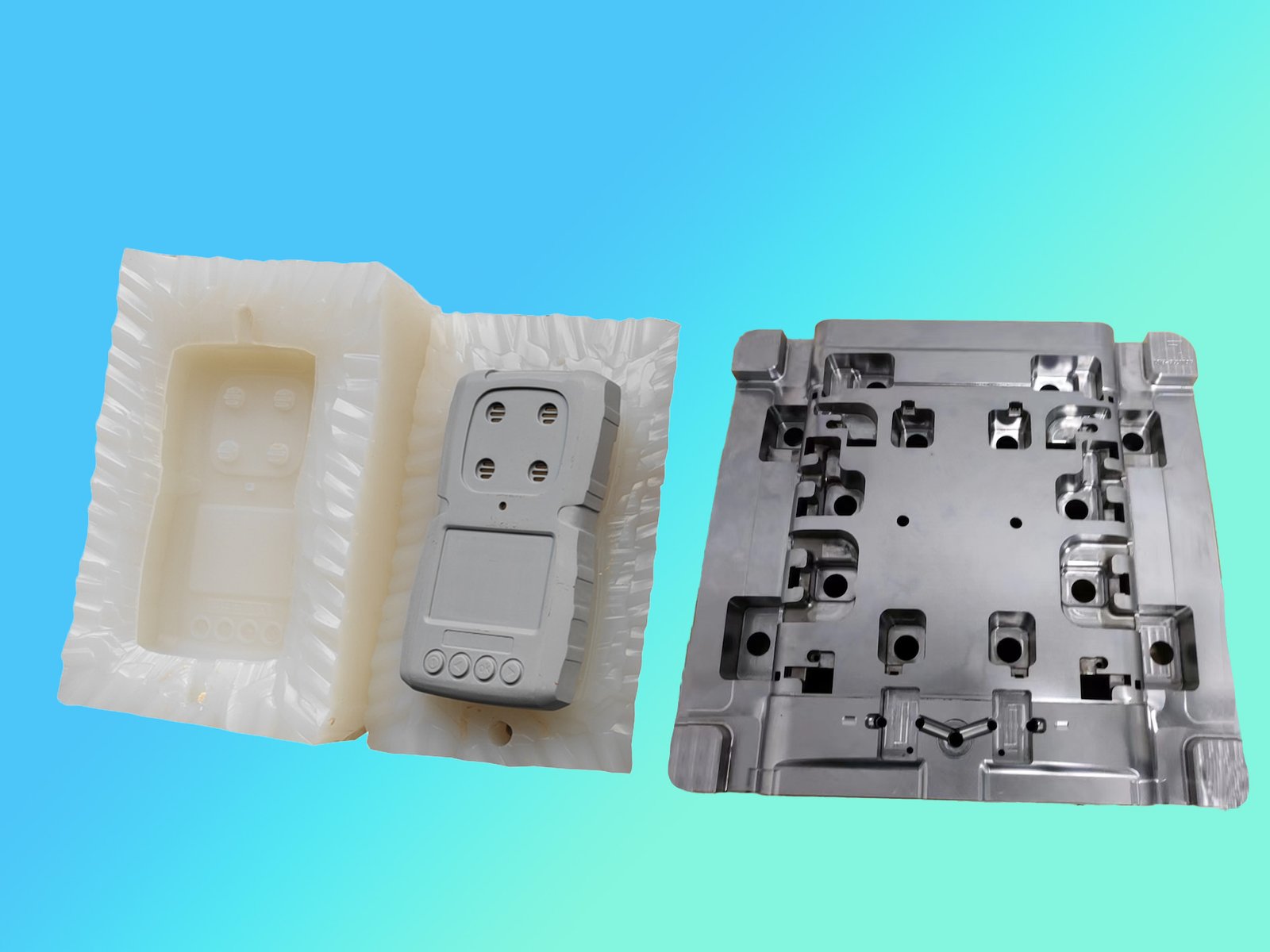

- Customization and Flexibility:

- As demand for customized products grows, tooling design is becoming more flexible. Modular tooling systems and reconfigurable designs are allowing manufacturers to quickly adapt to changes in product design and production requirements.

Conclusion:

The future of tooling design and manufacturing is marked by increased automation, the integration of advanced materials and technologies, and a strong focus on sustainability. These trends are driving the industry towards greater efficiency, innovation, and adaptability, ensuring that tooling remains at the forefront of modern manufacturing. As these developments continue to evolve, they will play a crucial role in shaping the future of production across various industries.